Target Drilling Ltd

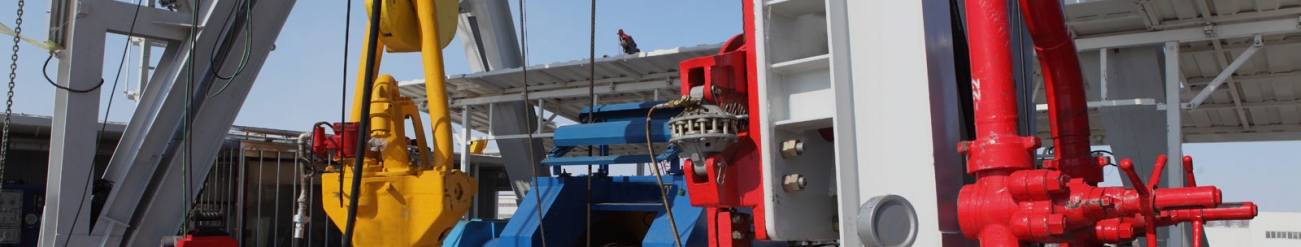

TARGET Drilling currently operates two (2) new active RDE U.S.A Hydraulic Workover Units:

GRACE-101: it’s a skid mounted with 340,000lbs workover capacity and 170,000lbs snubbing capacity and 10,000ft-lbs rotary capacity and

DIVINE-102: It’s a truck mounted with 340,000lbs workover capacity and 170,000lbs snubbing capacity and 10,000ft-lbs rotary capacity. Hydraulic Work-over Unit (HWU), basically, is a diesel powered and hydraulic operated unit used in generating push, pull and torsion forces on the work-string and completion tubing's for achieving specific tasks and objectives. Well configuration and objective determines the rig up mode (Snubbing, Workover and Drilling). Units are designed to rig up quickly and can be mounted on Christmas tree using a sub structure through which the force is transmitted to the well head. It can also be rigged up directly on the wellhead (THS) but it must be capable of supporting the weight of the unit and the forces generated during the pulling and push effect.

The unit are designed to handle pipe without the use of a conventional workover - rig. All components are compact and utilized to minimised rig up time. It operates in any terrain including land, swamp, shallow and deep offshore.

HWU three modes of Operation:

1. SNUBBING MODE: When the well is live and unit is rigged up on Christmas tree. Primarily for through tubing intervention. Well control barriers intensified both externally and internally.

2. WORKOVER MODE: When the well is killed (or dead). Christmas tree is removed and BOP’s/HWU unit is rigged up on the well head or on a substructure.

3. DRILLING MODE: When is mounted on a substructure and easy racking system used, rotary torque capacity increased. Fluid circulation, segregation and conditioning unit configured for drilling purposes

JOENY DRILLING'S HWU APPLICATIONS

The JOENY DRILLING HWU provides a highly cost effective, efficient and proven alternative from the conventional drilling/work-over rig. Its work, capability and experience scope covers all the following applications both for oil and gas wells with HT/HP conditions both on and offshore terrain.

a Running and pulling of production strings.

b Fishing of parted tubing or lost wire-line tools.

c Squeeze cementing or setting of cement plugs.

d TCP perforating.

e Gravel packing/ESS installation.

f Well abandonment.

g Milling/retrieval of permanent packers, cement retainers etc.

h Cement drill out operation.

i Completion or re-completion with packers, safety valves, gas-lift valve, ESP’s and flow controls.

j Well control services.

k Sand washing/well clean out services.

l Ability to Rig Up Coiled tubing, Slick and Electrical wire-line for Logging, setting of permanent parkers, plugs, slick-line operation, etc

m Acid washing and acid stimulation.

n Unloading with Nitrogen or foam.

o Drill Stem Test (DST).

The choice of unit for a particular job is determined by its suitability, capabilities, client’s preference and availability from their busy well work schedules with various operating companies. The HWU components are, jack assembly, rotary table, work window, work basket, counter balance system BOPs, gin pole, two power packs, tong pole, slip bowls, Accumulator unit & accessories.

ADVANTAGES

ON QHSE

1 Reduced exposure to hazards due to reduced personnel on location.

2 Reduced impact on environment due to compact nature of unit.

3 Reduced community attention on operations due to unconventionality

COST OPTIMIZATION BENEFITS

1 Avoidance of lost production associated with delays involved with mobilizing conventional rigs

2 Reduced mobilization and demobilization time as compared to a conventional work over system

3 Reduce total well cost by over 50% in offshore application unlike conventional Jack-up Rig.

4 Reduced crew size and logistic problem.

5 Can work in a space-constrained location (Offshore platforms).

6 Reduced rig-up & rig-down time

7 Reduced attention from host community due to small size of Unit compared to a conventional rig.